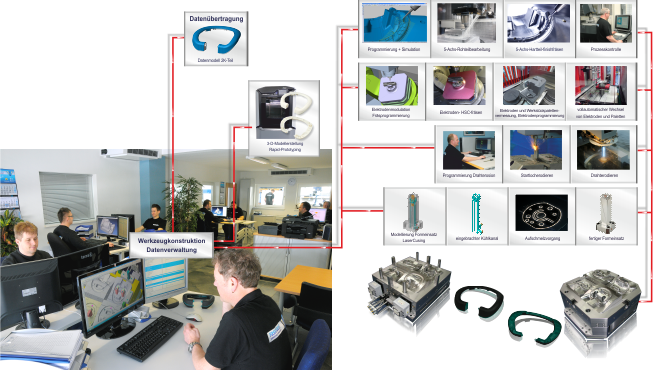

Data communication: Data model 2-component part

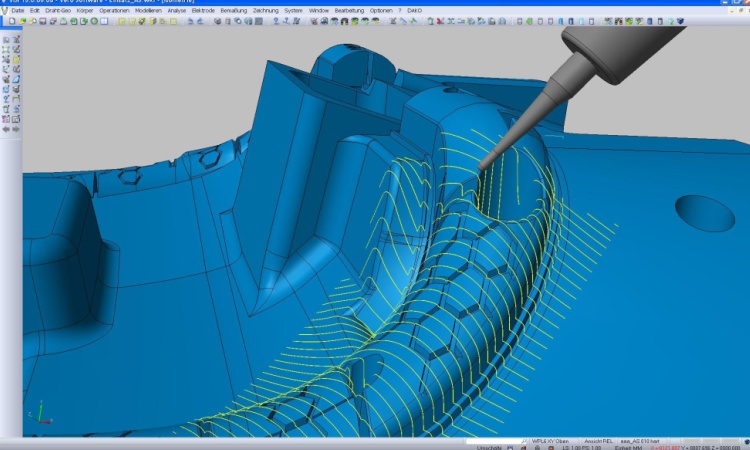

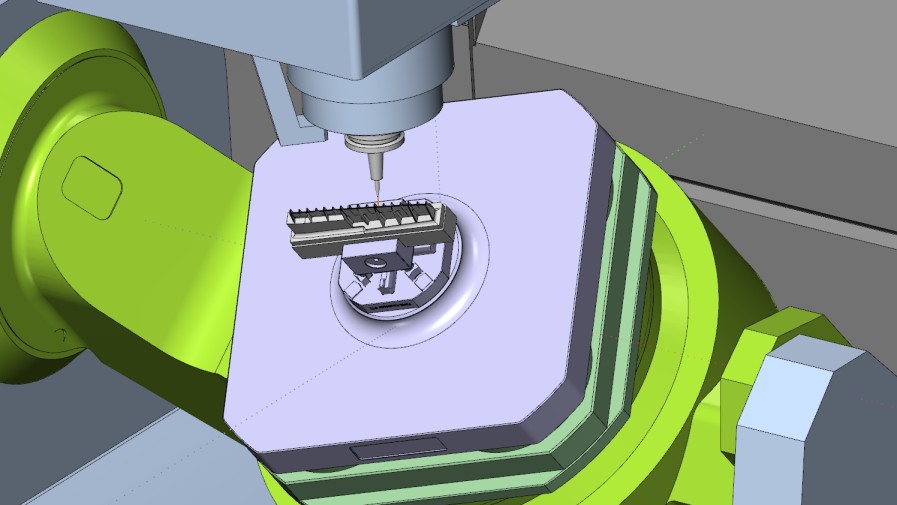

Programming and simulation

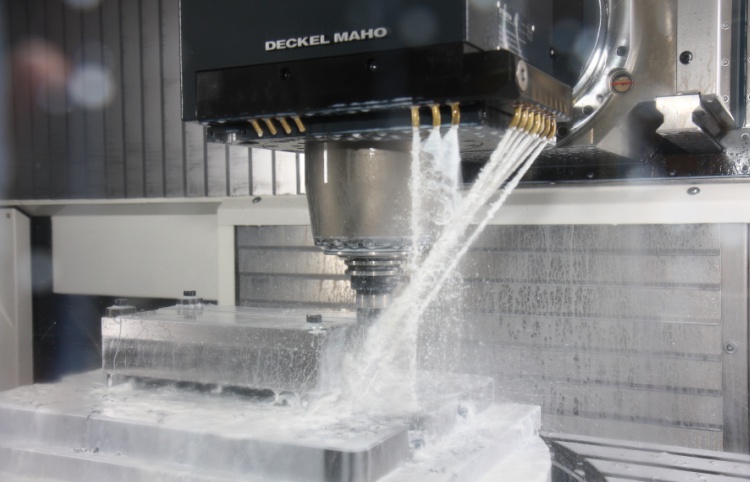

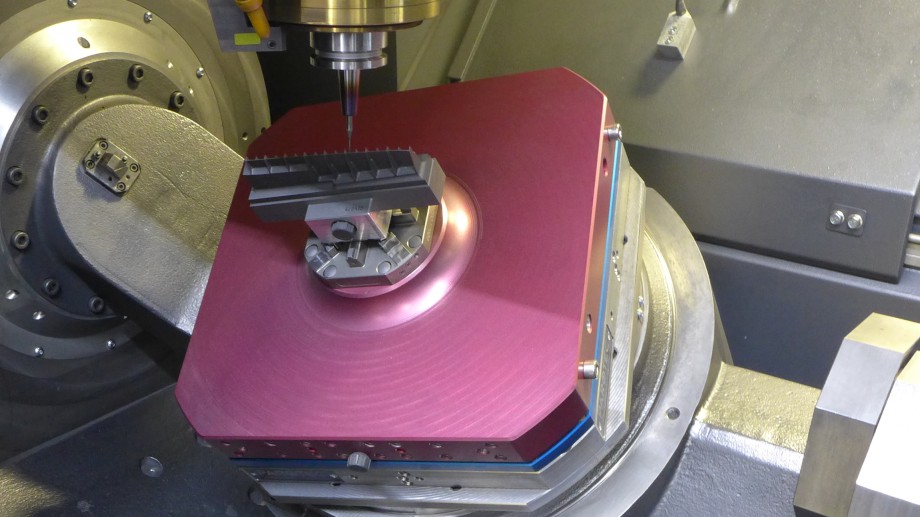

5-axis blank machining

5-axis hard part finish milling

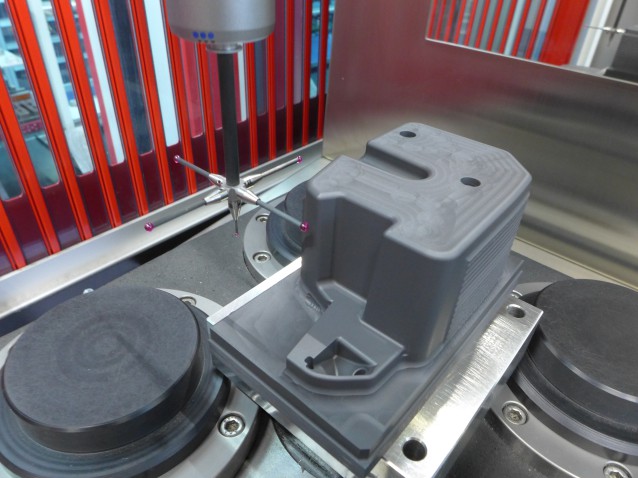

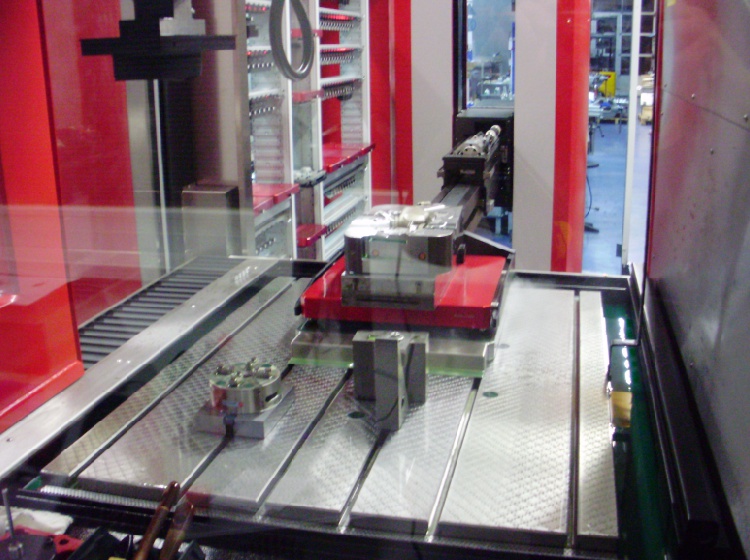

Process control

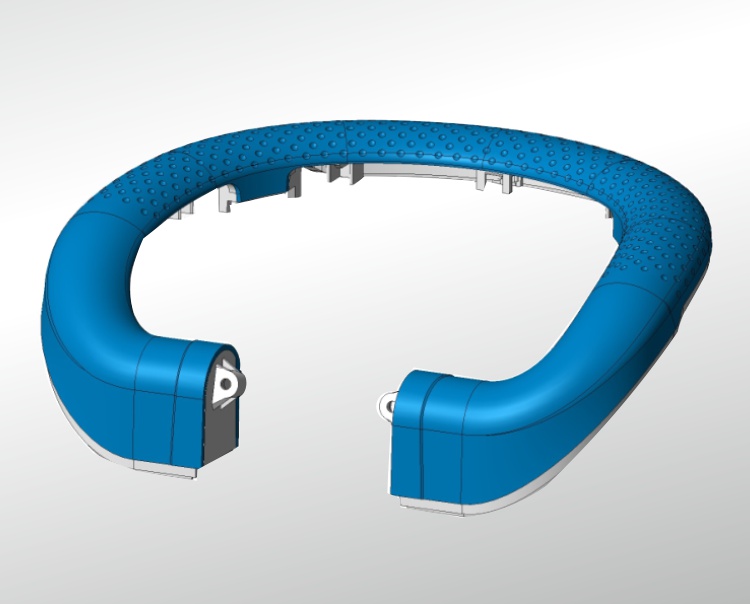

3D model creation - rapid prototyping

Electrode modulation, milling programming

Electrode HSC milling

Fully automatic electrode and workpiece measurement

Fully automatic changeover of electrodes and pallets

Programming of wire erosion

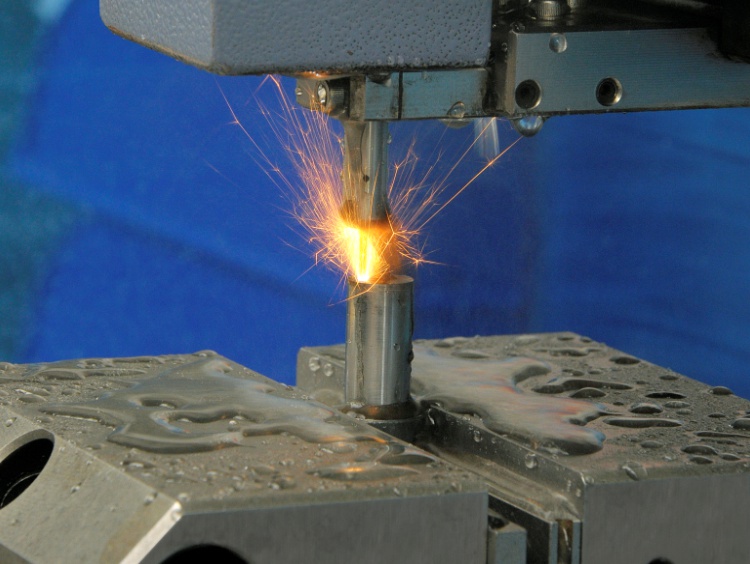

Start hole erosion

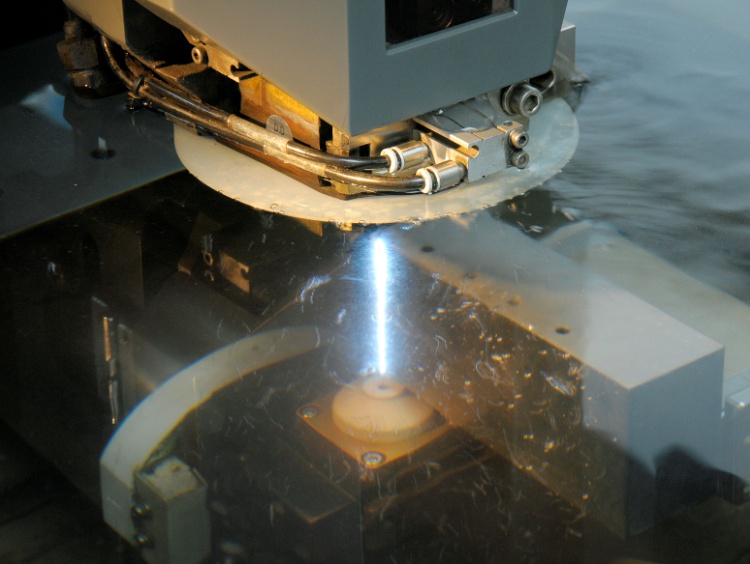

Wire erosion

Tool design - data processing

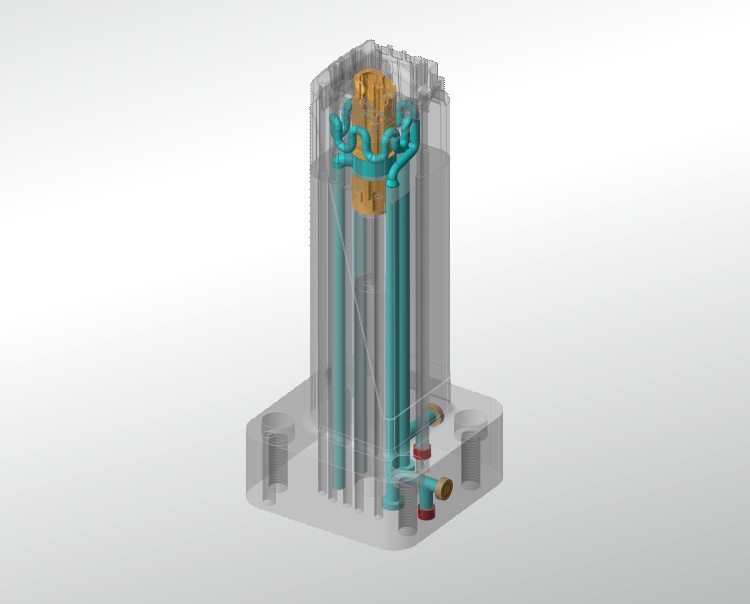

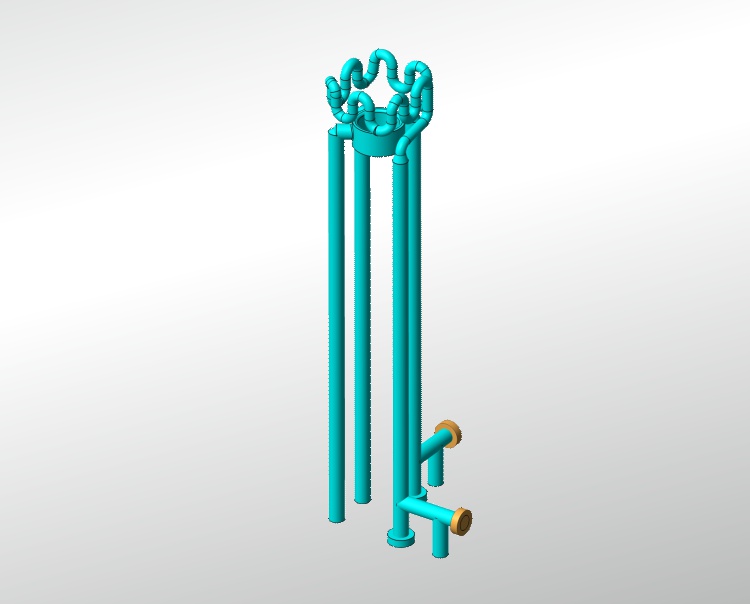

Mould insert modelling, LaserCusing

Incorporated cooling channel

Melting process

Finished mould insert